Toxicology and Safety

The HFCs, lower-GWP HFCs, HFC/HFO-blends and HFOs (including HCFOs) have favourable toxicity profiles and provide the required flammability properties necessary for a range of applications. Their safety properties, efficiency and technical performances enable these fluorocarbons to be used effectively in a wide range of applications.

Reducing Fire Risk

Where non-flammability is required, some HFCs, HFC/HFO-blends, HFOs and HCFOs are available and have proven technical performance. Nonflammability is an important requirement for many RACHP installations used in public places like theatres, supermarkets, transportation and transportation hubs, tall buildings. For some applications, mildly flammable fluorocarbons (lower-GWP HFCs, HFC/HFO-blends and HFOs) can be used and offer excellent technical performance, with lower GWPs compared to non-flammable HFCs.

Fire Risk is Real

Highly flammable (hydrocarbons) and toxic (ammonia) refrigerants, due to their safety profiles, have more constraints on charge size and applications. This is because the consequences of a loss of containment due to a leak or during servicing and maintenance can be severe, particularly for larger refrigerant quantities. Unfortunately, there are have been a number of incidents resulting in injury or death, or considerable damage to property due to such loss of containment.

ECHA Substance Information Infocards for HFCs, HFOs and HCFOs provide access REACH and C&L data.

RACHP

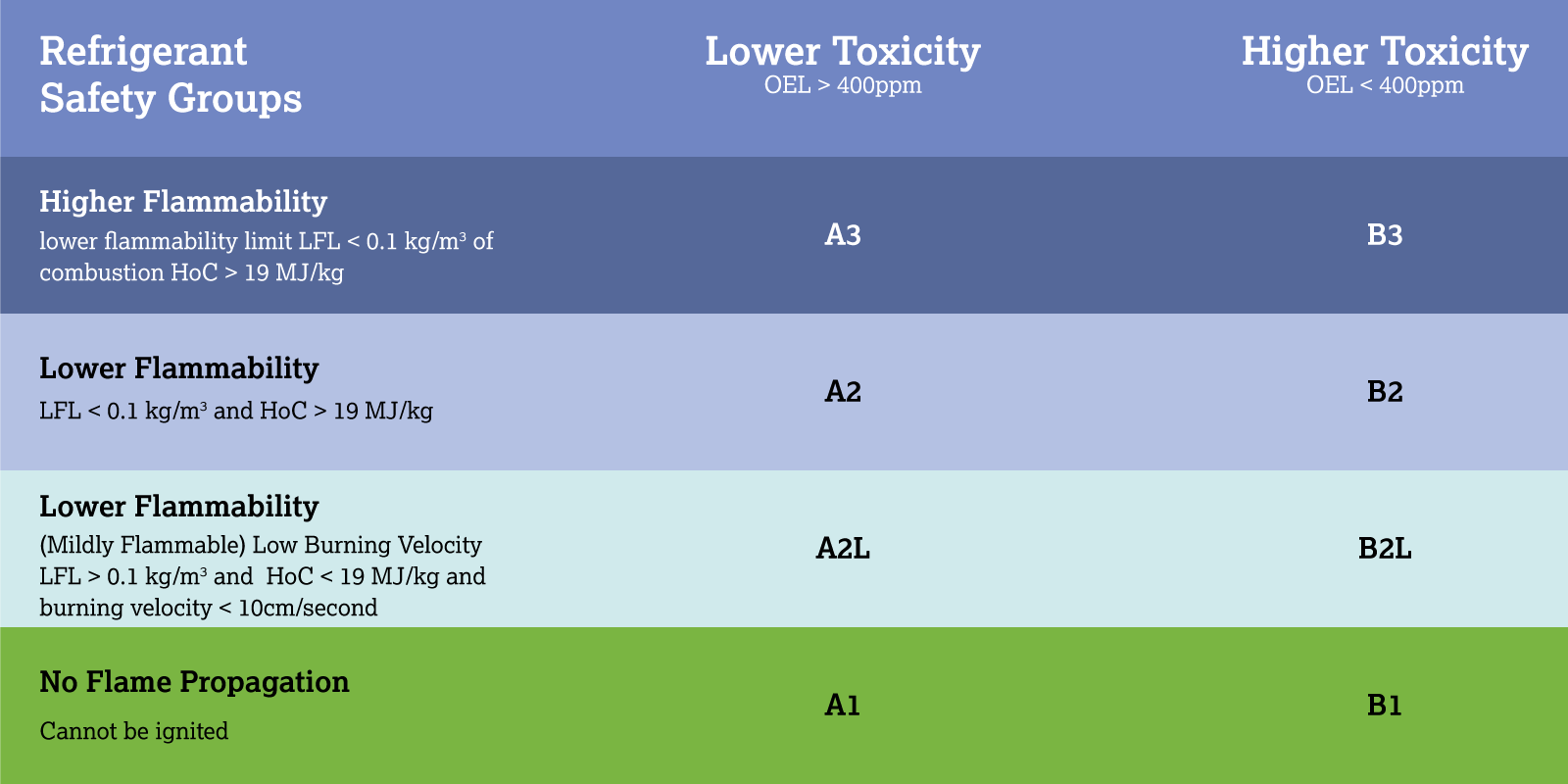

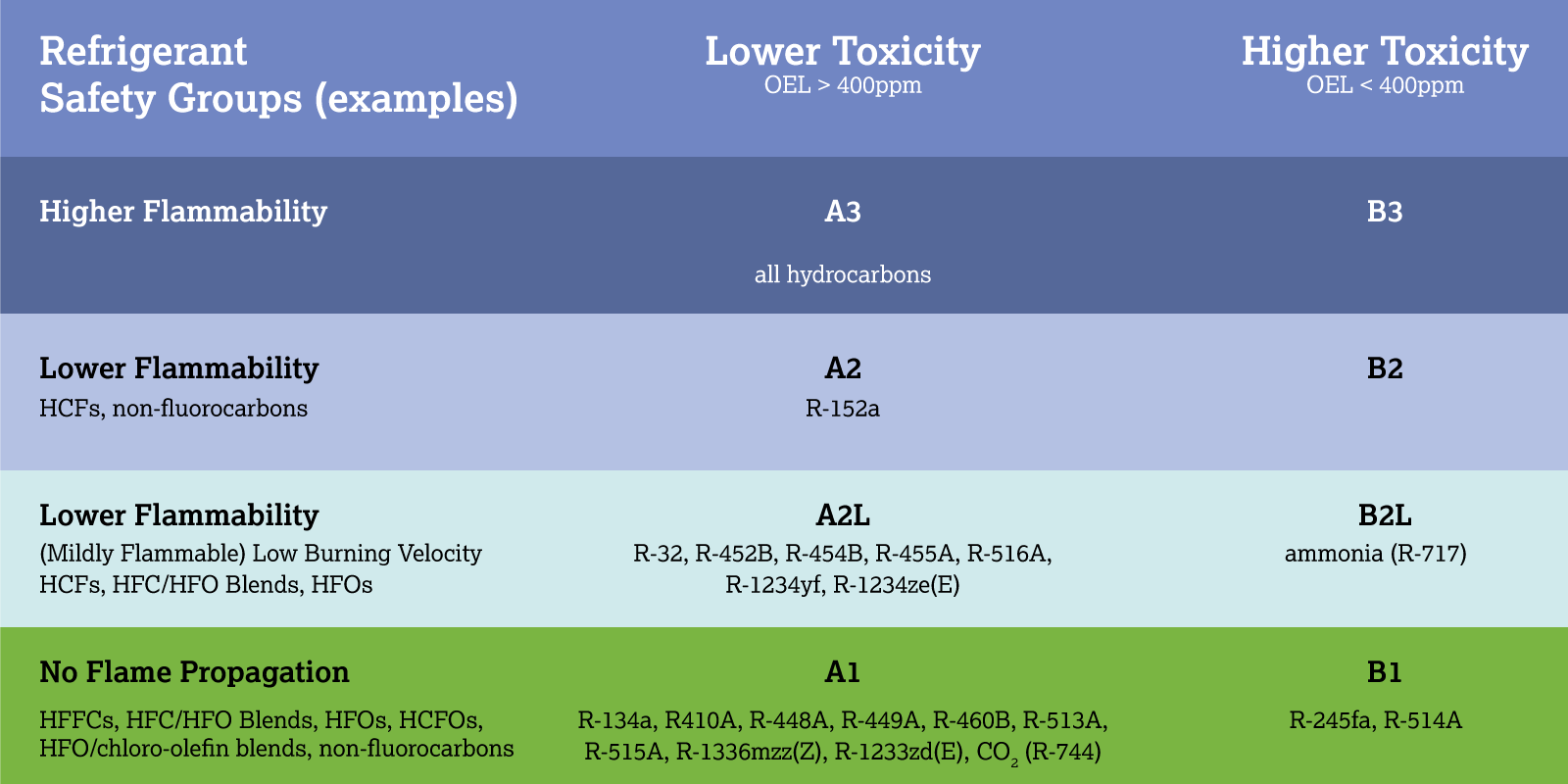

The tables show the safety classifications and some examples of refrigerants and their safety classification based on ISO817. For a complete list of refrigerant safety classifications see Refrigerants subject to the F-Gas Regulation 517/2014.

Standards, such as ASHRAE 34 and ISO-817, use refrigerant flammability and toxicity properties to define refrigerant classifications. The refrigerant safety data is generally developed by a refrigerant supplier and submitted for review by ASHRAE 34 and/or ISO 817 committees. The refrigerant classifications and specific properties such as the lower flammability limit (LFL) are used in standards such as EN378 and ISO 5149 to define refrigerant charge and allowable applications. ‘Mildly flammable’ refrigerants (A2L classification) have different calculations for maximum refrigerant charge when compared to other flammable refrigerants. Standard EN 378 also define risk mitigation measures for some classes of refrigerant.

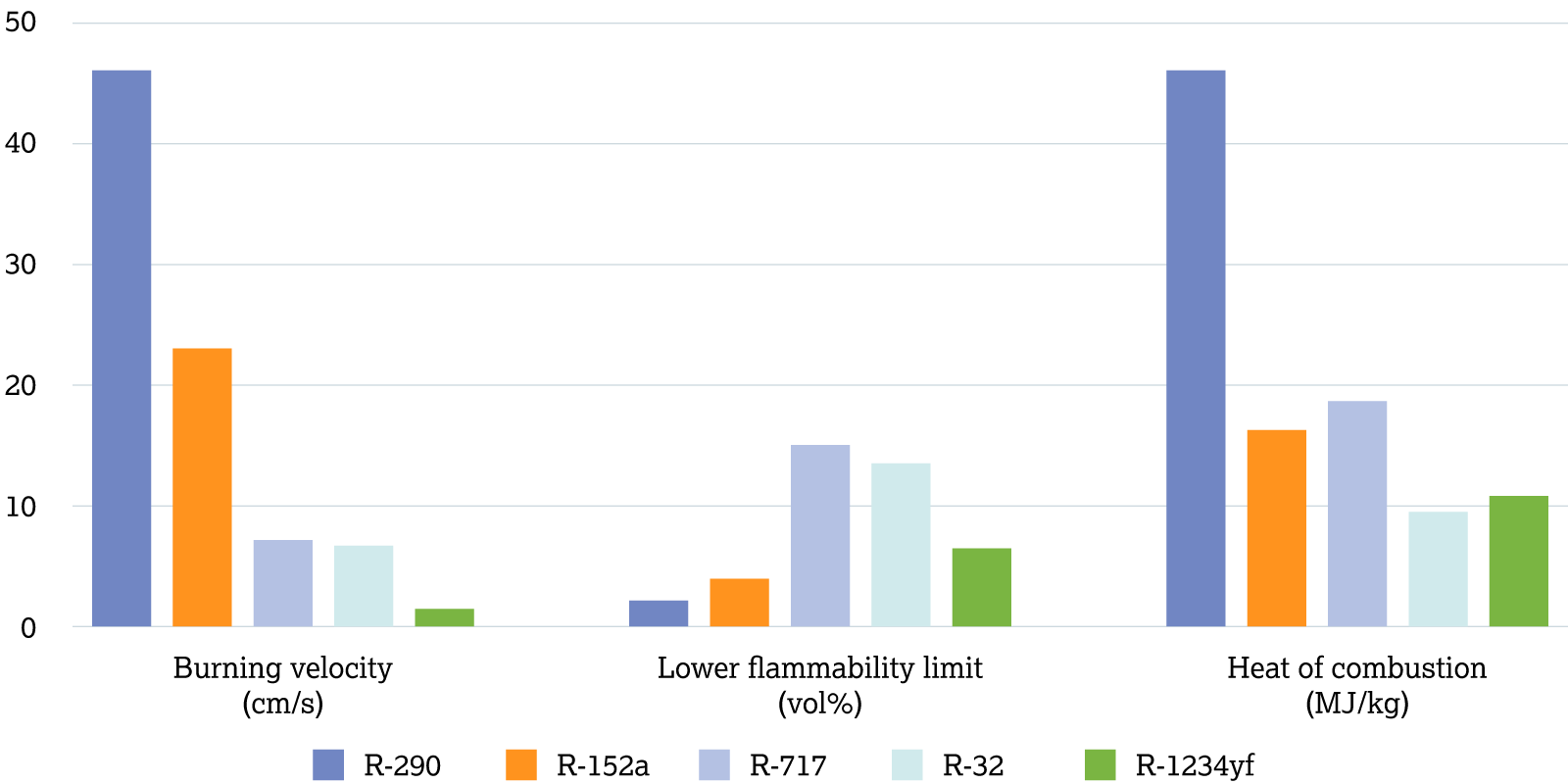

Flammability Properties

International and European safety legislation and standards such as ISO 5149, EN 378 and IEC 60335-2-40 define requirements to remain well below the lower flammable limit in case of accidental leakage. Other flammability properties determine the ease of ignition (minimum ignition energy) and the pressure rise for ignition in confined spaces. If a refrigerant is flammable, the classification properties used are:

- Lower flammability limit (LFL)

- Heat of combustion (HoC)

- Burning velocity (BV)

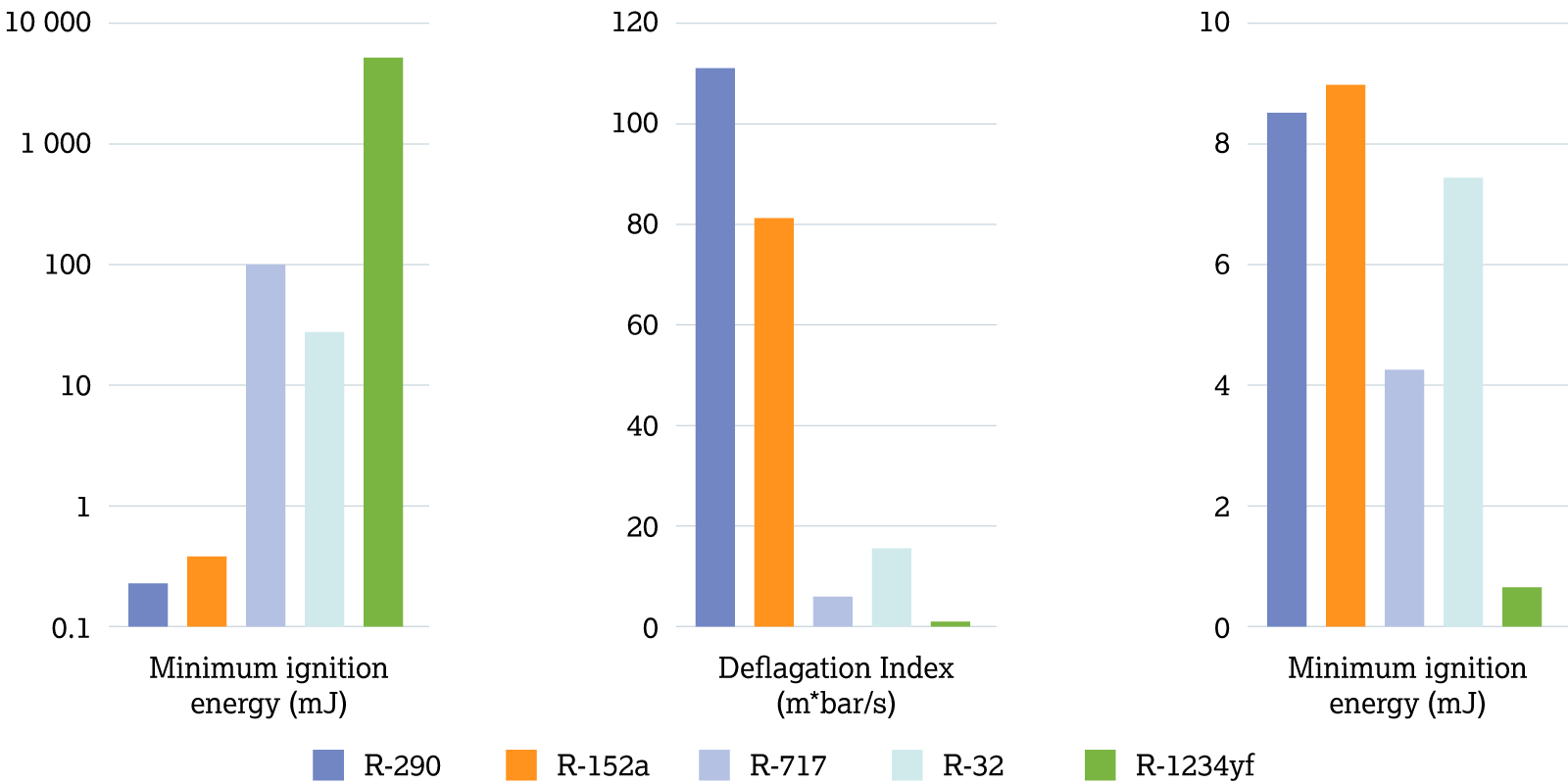

These are a subset of flammability properties which can also include:

- Upper flammability limit (UFL),

- Minimum ignition energy (MIE),

- Peak constant volume pressure rise for an enclosed combustion

- Deflagration index, measures the relative explosion severity, calculated from the maximum rate of pressure rise and the test vessel volume

Some of these properties are linked. The charts show flammability data for refrigerants R-290 (A3), R-152a (A2), R-717 (B2L), R-32 (A2L), and R1234yf (A2L). This data supports proposed links between flammability properties and helps explain why only three properties are used for refrigerant classification:

- Heat of combustion (HoC), peak constant volume pressure and deflagration index all relate to how energetic combustion is.

- Burning velocity [1]

- inversely correlated with the minimum ignition energy (higher burning velocities were more easily ignited by lower ignition energies)

- appears to be correlated to LFL and deflagration index

- little to no correlation was found between BV and the auto-ignition temperature, with the reason likely being the nature of the standard test for measuring AIT, which is conducted by heating the mixture on all sides

Auto-ignition temperature (AIT) and Hot surface ignition temperature (HSIT): AIT was originally used as one of the tests to classify refrigerants as nonflammable by UL- Underwriters Laboratories. When non-flammable HFCs were introduced, their AIT was lower than CFCs and UL classified them ‘practically non-flammable’. This had no relevance to their refrigerant classification by ASHRAE 34. More recently, for RAC equipment safety standards, it has been recognised that a test appropriate to a dynamic leak event has much greater relevance. AIT is a static contained event; in contrast hot surface ignition is a dynamic event where liquid refrigerant is sprayed onto a hot surface. HSIT is closer to real leakage events for RAC applications and is used in IEC 60335-2-40 Annex KK. HSIT shows that for a range of A2L refrigerants, HSITs are > 800°C. In addition, there is an ASTM standard for HSIT (ASTM Standard D8211-18). Independent flammability testing is also carried out, for example by SAE CRPs (Co-operative Research Programs) and the Japan Society of Refrigerating and Air Conditioning Engineers as part of risk assessments for the use of flammable refrigerants.

Toxicity

The refrigerant toxicity classification has 400 ppm Occupational Exposure Limit (OEL) as the divide between higher and lower toxicity refrigerants. All widely used HFCs (except HFC-245fa), HFOs and HCFOs are classed as low toxicity, with OELs in the range 400 to 1000 ppm. R514A (containing dichloroethane) is classed as B1. The hydrocarbon refrigerants are classified as low toxicity. ASHRAE 34 also cites, in its refrigerant data and safety classification table, the toxicity category of the International Fire Code and Uniform Fire Code regulations. The toxicity category is either highly toxic (LC50 ≤200 ppm), toxic (LC50 ≤ 2000 ppm) or neither (lesser toxicity than either of these groups). All the widely used HFCs, HFOs and HCFOs are in the ‘neither’ category. Ammonia has a OEL (time weighted average TWA) of 25 ppm and a short-term exposure limit (STEL) of 35 ppm, and according to ISO817:2014 an acute toxicity exposure level of 320ppm. The acute toxicity exposure level (ATEL) of refrigerants is used to determine toxicity based practical limits, with the maximum value being set by the limit of oxygen deprivation (ODL), which is 140,000ppm (14% v/v).

Other Applications

For other applications such as technical aerosol propellants and solvents, for storage and transportation of bulk fluorocarbon, and handling and use, other standards and requirements apply. The refrigerant safety classification is only used in reference to refrigeration, air conditioning and heat pump system safety. Transport regulations (ADR) and extended REACH compliant Material Safety Data Sheets do not use EN378 safety classifications. All flammable fluorocarbon refrigerants are classified as an extremely flammable gas. The exception to this is the HFO R-1234ze(E), which GHS classifies as non-flammable (at 20°C). Refrigerant safety classification assesses flammability at higher temperature. Links to the ECHA Substance Information Infocards for HFCs, HFOs and HCFOs providing access REACH and C&L data are here. MDIs: An inhalation propellant must be safe for human use and meet several other criteria relating to safety and efficacy which is why HFCs are the propellant of choice. More information about MDIs is here.

Notes:

[1] Journal of Loss Prevention in the Process Industries 49 (2017) 662 – 674, Flammability and explosion characteristics of mildly flammable Refrigerants, S.G. Davis, J.L. Pagliaro T.F. Debold, M. van Wingerden, K. van Wingerden. Note, some of the flammability data in this reference is different to that usually quoted for refrigerants, but different test methods can result in different results although with the same trends

[2] Risk Assessment of Mildly Flammable Refrigerants Final Report 2016, March 2017, The Japan Society of Refrigerating and Air Conditioning Engineers

[3] Summary of SAE CRP1234 Refrigerant Evaluation and Risk Assessment July 15, 2010

[4] IoR Guidance note 29: BS EN378:2016 – Summary of Changes